Flexographic printing, commonly known as flexo printing, is a versatile and efficient printing technique widely used for packaging and labeling. It utilizes flexible relief plates made of rubber or photopolymer to transfer ink onto a variety of substrates. The process begins with the creation of the printing plates, which are mounted on rotating cylinders. As the substrate moves through the press, ink is applied to the raised areas of the plate, transferring the image onto the material.

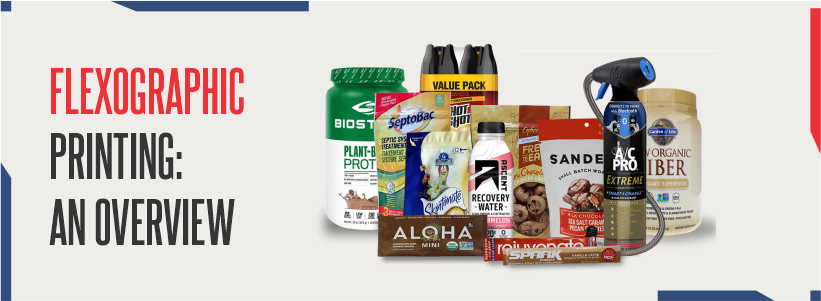

Flexo printing is known for its ability to print on a wide range of substrates, including paper, plastic, metal films, and even fabric. This adaptability makes it ideal for diverse applications such as food packaging, labels, corrugated boxes, and more. One of the key advantages of flexo printing is its high-speed production capability, making it cost-effective for large print runs. Additionally, advancements in flexo technology have significantly improved print quality, allowing for intricate designs and vibrant colors.

Overall, flexo printing offers a reliable and economical solution for businesses seeking high-quality printed materials across various industries. Whether you need large quantities of labels or intricate packaging designs, flexo printing provides the flexibility and efficiency to meet your needs.